Mannacote is gaining attention for its advanced surface protection technology. Industrial managers face costly corrosion. Maintenance d rain resources. The problem: protective coatings fail too soon. The solution: Mannacote, a smart, self-healing, eco-friendly coating system that extends asset life, reduces cost, and delivers reliable durability.

1. What Is Mannacote? A Primer

Mannacote is not a single material, but a family of adaptive surface coatings. It’s built on smart polymers, often embedded with microcapsules, antimicrobial agents, or memory-based materials. These allow the coating to respond to stimuli like heat, wear, or moisture. This technological leap redefines surface protection in multiple industries.

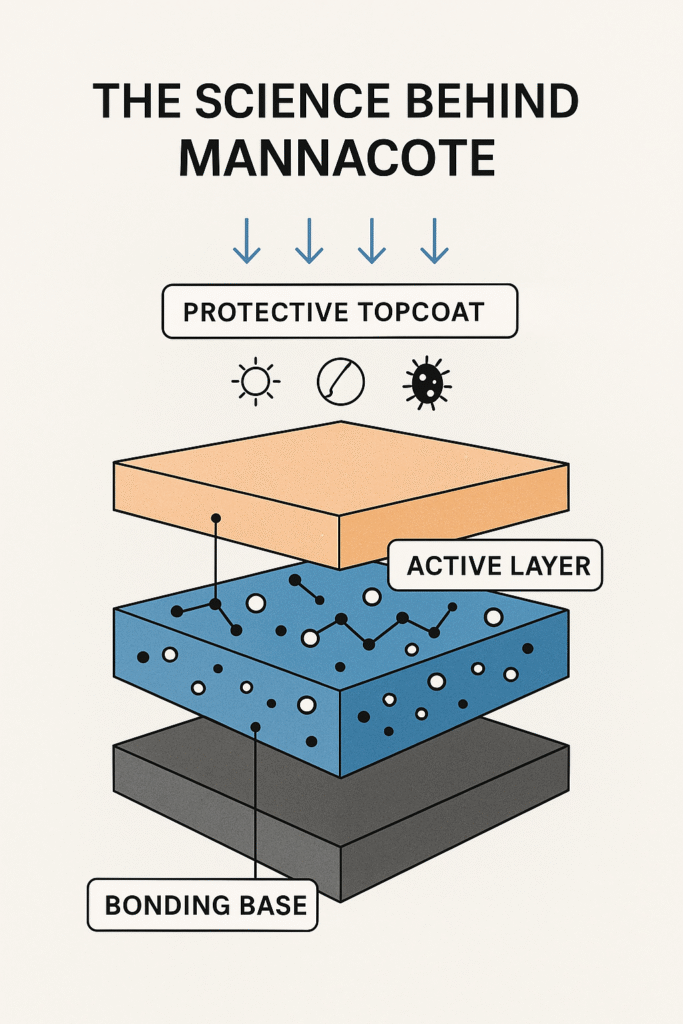

2. The Science Behind Mannacote

At its core, Mannacote employs multilayer chemistry. A bonding base adheres to materials like metal or concrete. An active layer contains nanocapsules or polymers that adapt or self-heal. The final interface provides UV resistance, hydrophobicity, or microbial protection. Applied via spray, roller, or spray polymerization, it transforms surfaces into intelligent barriers.

3. Key Features That Make Mannacote Smart

- Self‑healing properties: repairs microcracks on its own.

- Bio‑adaptive compatibility: some variants are FDA‑approved for biomedical use.

- Nanotechnology: enhances adhesion and scratch resistance.

- Thermo‑responsive or antimicrobial formulations: e.g. silver-infused for hygiene.

- Durability under extreme weather: maintains bond under expansion and contraction.

4. Benefits of Mannacote Surface Coating

Mannacote provides:

- Superior corrosion resistance on metal and concrete.

- Chemical and abrasion resistance, ideal for factories or labs.

- Weather and UV stability, retaining color and integrity outdoors.

- Eco-friendly formulas, often low‑VOC and non‑toxic.

- Cost savings through reduced maintenance and longer asset life.

5. Applications of Mannacote

Industrial Coating: protects pipelines, machinery, and refineries.

Marine & Offshore: shields ship hulls, docks, and offshore rigs from saltwater corrosion.

Construction & Infrastructure: used on bridges, parking garages, and floors.

Commercial/Residential: roof coatings, decorative finishes, flooring.

Biomedical & Food-Processing: safe variants for implants or food-safe surface channels.

6. How to Apply Mannacote Correctly

Surface prep: clean, degrease, sand, or blast.

Primer application: Use zinc-rich or epoxy primer if needed.

Coating method: spray, roller, or brush with thin, even layers.

Curing time: typically 24–48 hours for full bond strength.

Quality checks: inspect for bubbles, peeling, or incomplete coverage.

7. Industries Turning to Mannacote

- Aerospace (aircraft casings)

- Biomedical (surgical tools, implants)

- Energy (wind turbines, pipelines)

- Food & beverage (sanitary coatings)

- Manufacturing and agriculture (machinery, equipment).

This research shows how adaptive, high-performance coatings meet diverse sector needs.

8. Mannacote vs Traditional Coatings

| Feature | Traditional Coatings | Mannacote |

| Durability | Moderate | High, with self-healing |

| Chemical resistance | Low to medium | High |

| Environmental safety | Often VOC-heavy | Low-VOC, eco-friendly |

| Cost over time | Frequent maintenance | Reduced maintenance, longer lifespan |

| Application modes | Limited | Versatile: spray, roll, brush |

In summary, Mannacote outperforms conventional systems in every critical dimension.

9. Smart Surface Science: Mannacote Technology

With smart polymer matrices, adaptive nano-materials, and self-healing chemistry, Mannacote embodies next-gen surface protection. Its coating behaves like a living system: sensing, adapting, and repairing when needed. This aligns with future trends in material science and smart manufacturing.

10. Limitations & Considerations

- Higher upfront cost versus regular coatings

- Requires trained application and specialized equipment

- Proprietary or variable formulations may lack uniform standards

- Some variants still need validation in medical or consumer markets

11. Future Trends & Market Outlook

Innovation continues:

- Self-monitoring coatings that change color or texture with stress

- Nanotech-infused variants for scratch resistance

- Biocompatible and biodegradable versions for medical, food, or consumer use

- AI-guided formulation workflows to accelerate customization.

12. Why Mannacote Matters Now

Mannacote bridges practical needs with smart technology. It answers pressing problems: corrosion, downtime, and environmental risk. Its formulation aligns with modern values: sustainability, durability, and adaptability. It is not just a coating. It is surface science for the modern age.

Conclusion

Mannacote stands out as a smart surface science solution—not just a coating. By combining adaptive polymers, self-healing capabilities, and eco-friendly formulations, it outperforms traditional coatings in durability, safety, and cost-effectiveness. Whether on heavy steel infrastructure, medical implants, or marine environments, it preserves assets and extends life while meeting environmental standards.

For engineers, facility managers, and innovators, Mannacote offers real efficiency gains and long-term reliability. As technology advances and sustainability becomes essential, Mannacote’s smart coating technology is poised to lead the future of protective surfaces.

This author regularly contributes to Mannacote, focusing on practical, easy-to-understand articles across tech, health, business, lifestyle, and food. With a commitment to clarity and real-world relevance, their content is designed to inform, guide, and inspire readers at every stage of life.

Visit: https://mannacote.com.in/